40 steps to the construction site in Bensheim, south Hesse

This usually means a lot of strenuous carrying work. But there is another way. This is shown on the example of a terrace renovation in Bensheim in southern Hesse. For the large-format ceramic elements, the tiler opted for a new, material-saving and weight-saving way of laying the tiles – and therefore solved a number of other problems in an elegant and easy way.

There is nothing better than sitting in the vineyards of the Hessian Bergstrasse in summery weather and enjoying the evening. At least that's what the owner of an apartment in Auerbach, a district of Bensheim, thought. And that's why he decided to completely renovate his 15 square meter terrace. In the 1980s, the usual exposed aggregate concrete was laid loosely on gravel. Uneven coverings, weeds in the joints, unattractive surface: this is what the terrace looked like now. Bigger ceramic tiles are to be used as the new covering – despite the unbonded substrate.

But there were other challenges. The laying was to be carried out in November, i.e. before the start of winter, meaning that there was a tight schedule and the prospect of inconsistent weather and temperatures around freezing point. The client also wanted closed joints for the large ceramic elements – which had to be laid around the numerous supporting beams from the balcony above. And last but not least, all of the material for the terrace renovation had to be carried up 40 steps – time-consuming and strenuous work.

These issues encouraged the installer to use a new, mortar-free laying system made from lightweight aluminium on this construction site. Because this has been developed for applications such as this, among other things, saves time and is particularly light and can be used regardless of the weather.

About 40 % less working time required

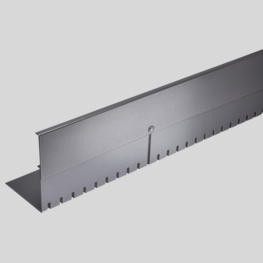

The new TerraMaxx RS laying system consists of aluminium frames on which the covering can be laid directly and loosely. The profiles are joined together at the construction site using special quick connectors. The only tool required for this is an Allen key. As a result, the frames were connected securely and above all quickly, and the level surface was ready after just eight hours. That was also possible because the work could be carried out despite the cold temperatures. According to the tiler's estimate, he was around 40 percent faster in this way than when laying on (drain) mortar, especially since this would only have been possible in better weather conditions. The weight reduction was also considerable: rather than about 190 kg per square meter with mortar-based installation, the tradespeople only had to carry around 60 kg of material per square meter up the 40 steps. The bottom line is that this results in several clear positives for the new system.

Laying in bad weather

Balconies and terraces can also be filled in during bad weather – with mortar-free products such as the TerraMaxx RS aluminium frame system.

The rest of the installation also went smoothly. The installers first placed a sliding fabric onto the aluminium frame. This creates a decoupling layer between the frame and the covering, which makes sense because aluminium expands more than ceramic. They fixed the tile spacers to it with a self-adhesive foot. Finally they laid the ceramic elements – almost completely within a day. The reason for the quick work was that the aluminium frame system forms a really level substrate onto which the large formats can be laid directly, without any time-consuming levelling work.

Closed joints with loose laying

The following day the joints were closed – which is actually unusual for loosely laid coverings. However, many this is exactly what many clients want. This is why Gutjahr brought the MorTec SOFT special joint filler onto the market seven years ago. The elastic compound has a fine-grain structure and is therefore visually reminiscent of cementitious joints. The filler can be used as a covering and movement joint, because the tension reduces from slab to slab. The joint is very tear-resistant and weatherproof, and the entire surface is easy to clean

Easily adjustable falls

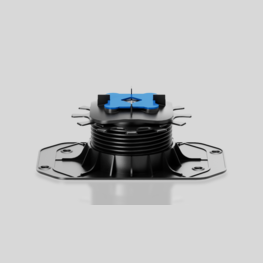

Another problem on the construction site in southern Hesse was that there was no fall in the substrate. However, the frame system is also suitable for this. In this case, the installer placed height-adjustable raised floor supports at the corners of the fully assembled frame. This allowed him to adjust the fall quickly and easily – even without tools. Because he also decided to use a Gutjahr system. The raised floor supports were also able to compensate for undulations in the substrate, because the "head" can be moved.

Positive conclusion

The tiler and the client both drew a positive conclusion after the work was completed. Because by using the mortar-free system, the terrace was able be completed within two days – even in the cold temperatures. Nor did the installers have to carry heavy bags of mortar upstairs. This also played a part in the quick completion: the 15 square meters were completely laid and grouted after two days. And finally the client got exactly what he wanted: a spacious terrace area with closed joints.

Products used

Similar project reports

![[TRL] Gutjahr Systemtechnik GmbH - Komplettsysteme für den Außen- und Innenbereich](/build/images/gutjahr-logo.d62773db.svg)