Garage renovation on oily substrate

Cracks in the screed and oily floor: the renovation of the garage couldn't be put off any longer – particularly since it accommodates a particular gem in the form of this English classic car. In order to be able to lay ceramic tiles on this tricky substrate, the installers relied on the IndorTec FLEXBONE-2E floating decoupling system from Gutjahr. The result is a permanently stable, easy-to-clean substrate – and an appropriate environment for the classic car.

Renovated with ceramic tiles

The house was built in 2004, when the garage was given a simple screed floor. However, over the course of time, the oil which the classic car inevitably loses made the floor oily. There were also cracks in the screed and flaking in the entrance area. The client therefore decided to renovate the garage and have a large-format tile covering put down which would not only improve the appearance but would make cleaning easier and oil stains easier to remove, since they cannot be avoided beneath the classic car.

The decision was made to use 80 x 80 cm ceramic tiles from Villeroy & Bosch. However, the large-format covering was not easy to lay due to the type of substrate. The tiles were to be laid directly onto the 15-year-old screed floor, which would not have been possible because of the oily substrate. The cracks and flaking in the screed also required decoupling between the tile and the screed. In consultation with the Gutjahr application technology department, the installers recommended the IndorTec FLEXBONE-2E decoupling system.

Floating laying

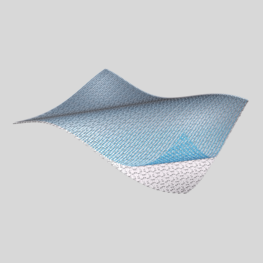

Also suitable for critical substrates: IndorTec FLEXBONE-2E can also be used on adhesive-resistant substrates.

Decoupling system for critical substrates

The special feature of the decoupling system is the floating installation. IndorTec FLEXBONE-2E not only decouples 100%, but can also be used on adhesive-resistant substrates. The combination of the laminated mesh fabric, the mat, the adhesive and the covering creates an independent covering carrier. This system, which has been developed for laying ceramic or natural stone coverings indoors, is therefore mainly used on critical substrates such as this one, where the substrate is cracked and oily. This decoupling system can also be used for interchangeable coverings such as the ones used in shopfitting.

Stable overall construction

In the double garage on Bergstrasse in Hesse, the tilers applied the low-shrinkage, 2-component Ardex K 60 levelling compound onto the IndorTec FLEXBONE-2E decoupling system, and then laid the new tile covering using Ardex X 90 tile adhesive. The covering was then grouted with the heavy-duty and chemical-resistant ARDEX RG 12 epoxy grout. The interaction of the individual components ensures that the overall structure is very stable.

Important to know: The floating decoupling technology has been tried and tested for almost 20 years. Thanks to the perfectly coordinated work materials and laying systems, the work was carried out quickly and without problems. Because of the loose laying, there was no need for extensive substrate work, even on difficult substrates. The installers were not put under any unnecessary time pressure – all they had to put up with were the high temperatures of the hot summer of 2019 during the work.

Satisfied client

The result was a renovated garage with a high-quality, floor covering that was completely solid and stable, even a year later, and a satisfied client who quickly got an easy-to-clean parking space for his English classic car, and the Triumph also seems to feel really at home in the new ambience.

Products used

Similar project reports

![[TRL] Gutjahr Systemtechnik GmbH - Komplettsysteme für den Außen- und Innenbereich](/build/images/gutjahr-logo.d62773db.svg)