Runs like clockwork: multi-level concept for the roof terrace of watch manufacturer Rolex

A combination of quality and precision is the top priority for watch manufacturer Rolex. This applies to the manufacture of both the top-quality watches and the new building at the Biel location in Switzerland. Whereas the filigree clock components are stored and distributed inside, the roof which is designed like a park acts as a terrace for the restaurant and a break area. The expansive granite surfaces must be extremely resilient – and also remain attractive over the long term. A real challenge with a roof with a 0˚ slope.

Rolex has reorganized and streamlined its entire clockwork production in Biel. The heart of the new glass building is the multi-storey high-bay warehouse with more than 46,000 storage locations. All of the components required for the clockworks are taken to the watchmakers in the various workshops from here: This is done via a fully automatic conveyor belt system which runs across the entire production building. Around 2,900 clockworks can be assembled every working day.

As well as the newly constructed production area, additional office workplaces, a restaurant, a library and an auditorium have been created. The building now features a roof terrace, which acts as a green oasis of relaxation for the employees and the restaurant visitors.

Roof terrace with different load zones

Granite walkways lead visitors along flower beds across the terrace. It may have a lightweight and elegant look, but it makes extreme demands of the resilience of the structure, because high-quality natural stone slabs have been laid over an area of 3,000 square metres. A heavy window cleaning lift weighing 5,000 kg is also anchored to the edge of the roof. The logistics alone were a daunting task: each pallet of granite slabs weighed 2 tons, and had to be temporarily stored at precisely specified locations so as not to overload the roof. Then it was a matter of laying the slabs by hand, because heavy equipment could not be used on the roof surface.

Resilient and reliable

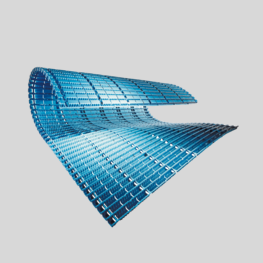

AquaDrain HU can also be used on roof terraces – even without a fall! The system provides a reliable solution and prevents permanent damage.

3,000 m² of natural stone on a roof with a 0˚ fall – a real challenge

The roof areas of the new building were designed without a fall. This means that seepage water can accumulate up to a height of 12 mm. Direct laying in the gravel bed was therefore a no-no, because gravel and grit are not capillary passive. If water is present on the waterproofing, it migrates back up via the construction, resulting in unsightly moisture stains and weeds in the joints. The second problem: the weight. The required thickness of the drain layer would have increased the load and caused problems with the statics. A solution had to be found that reliably drains the seepage water and does not put an additional load on the roof at the same time.

Drive-on surface drainage for the edge area

The biggest load on the roof is on the one meter wide edge strip which is used by the lift. For this reason, the AquaDrain HB-B surface drainage mat, which has been specially developed for concrete surfaces that can be driven on, was used there. A concrete covering was then put onto this.

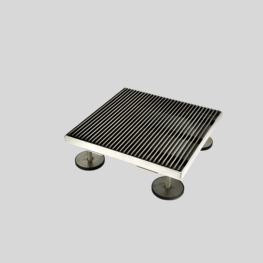

The 40 x 40 cm AquaDrain DR gully grids with continuous height adjustment above the floor drains. 8 cm thick granite slabs were laid on top of this. Instead of a grating, the granite was cut to the size of the frame, provided with drainage slits and inserted. The floor drain is therefore hardly visible, and the harmonious overall picture has been retained. The gully grids also allow an inspection to be carried out there at any time.

Good timing

The gardening and landscaping team had just four months to turn a grey roof into a green adventure island. The solid basis for the demanding requirements was construction using Gutjahr drainage mats. And the 2,000 or so employees in Biel will be able to look forward to their airy, permanently beautiful break area.

About Rolex

Renowned Swiss luxury watch manufacturer Rolex has stood for quality and prestige for more than a century. With headquarters in Geneva and a network of 28 branches and 4,000 watchmakers in more than 100 countries, the company is continuing its history which is rich in achievements and innovations.

Products used

Similar project reports

AFG Company Headquarters, Thurgau, Switzerland

New construction of outdoor area with natural stone

![[TRL] Gutjahr Systemtechnik GmbH - Komplettsysteme für den Außen- und Innenbereich](/build/images/gutjahr-logo.d62773db.svg)